The Ultimate Overview to Expanding Life Expectancy: Undercarriage Parts Maintenance Made Easy

Wiki Article

Optimize Efficiency With Sturdy Undercarriage Parts

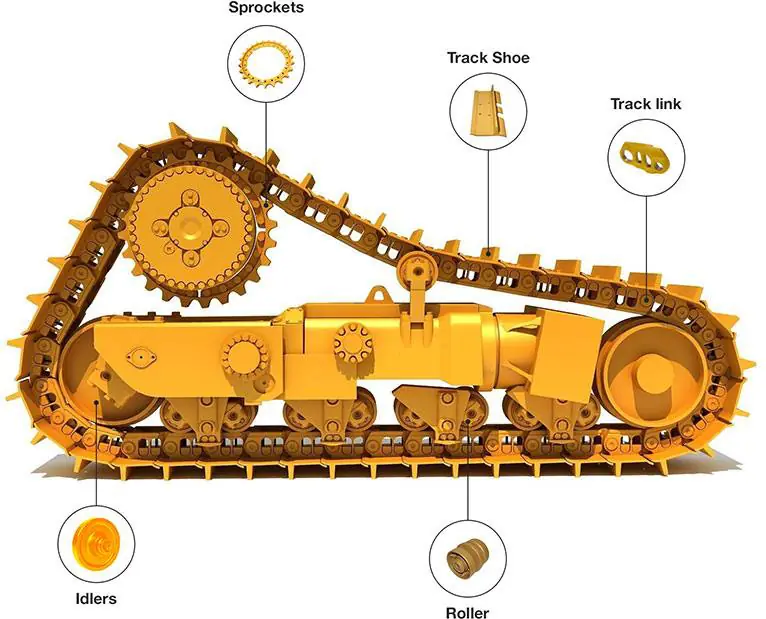

In the realm of heavy equipment and tools, the role of undercarriage parts is paramount in making certain optimal performance and long life. The efficiency and efficiency of these parts can considerably influence the total operation of machinery, making the option of durable undercarriage components a vital decision for managers and drivers alike.Advantages of Utilizing Sturdy Undercarriage Parts

Using durable undercarriage components not just improves the longevity of heavy equipment however additionally minimizes upkeep prices substantially. By spending in high-quality undercarriage parts, such as tracks, idlers, sprockets, and rollers, equipment operators can experience enhanced uptime and enhanced overall performance.

In addition, the durability of hefty equipment is directly linked to the high quality of its undercarriage components. Durable elements can stand up to the roughness of requiring applications, guaranteeing that the devices continues to be functional for extended periods. Consequently, operators can prevent pricey downtime and upkeep expenses, ultimately taking full advantage of the return on financial investment for their equipment.

Factors Impacting Undercarriage Toughness

The sturdiness of undercarriage parts in heavy equipment is influenced by numerous essential variables that directly impact performance and durability. Top notch materials, such as hardened steel, are important for standing up to the severe problems and hefty lots that undercarriage components are subjected to - undercarriage parts.Additionally, ecological aspects can have a substantial effect on the longevity of undercarriage components. Exposure to unpleasant products, extreme temperature levels, and harsh working problems can accelerate deterioration on undercarriage parts. Selecting undercarriage parts that are specifically developed to endure these environmental difficulties is important for ensuring resilience.

In addition, the style and design of undercarriage components have a straight impact on their resilience. Parts that are created to disperse lots equally, reduce friction, and reduce anxiety focus are most likely to have a longer lifespan - undercarriage parts. By considering these crucial elements, devices operators can maximize the resilience and performance of their undercarriage components

Maintenance Tips for Prolonging Undercarriage Life

Implementing regular maintenance regimens is essential for extending the lifespan of undercarriage components in heavy equipment. To lengthen the undercarriage life, it is crucial to frequently inspect for wear and tear. On a regular basis examine for absent or loose bolts, damaged rollers, or misaligned tracks, as these concerns can rise and cause additional damages if not resolved promptly. Additionally, guarantee that the undercarriage is appropriately oiled according to supplier standards to reduce friction and prevent premature wear.Another vital upkeep idea is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can speed up wear and rust, causing costly repairs. Cleaning the undercarriage after use this link procedure in rough problems is suggested to avoid these concerns.

Finally, tracking and recording upkeep tasks can help in creating an aggressive maintenance schedule. Maintaining in-depth records of substitutes, repair work, and examinations can provide valuable understandings right into the undercarriage's problem and efficiency gradually, assisting in predicting and stopping prospective failings. By following these maintenance suggestions faithfully, drivers can considerably boost the resilience and performance of undercarriage parts in heavy machinery.

Choosing the Right Undercarriage Parts

Choosing suitable undercarriage parts is critical for taking full advantage of the efficiency and longevity of hefty equipment. When it comes to selecting the best undercarriage elements, there are several factors to consider.Deciding for credible brands understood for creating durable and high-performance undercarriage components can considerably affect the overall performance and longevity of the machinery. By carefully selecting the appropriate undercarriage components, tools proprietors can boost performance, lower downtime, and expand the life-span of their hefty equipment.

Study: Boosted Performance With Durable Components

Integrating durable undercarriage parts has actually address shown significant enhancements in equipment performance. One situation research involved a building firm that upgraded its excavator's undercarriage elements to extra resilient choices.In an additional instance, a mining operation changed the undercarriage components of its bulldozer with premium, sturdy alternatives. This switch brought about a remarkable enhancement in the excavator's ability to move and overall performance. The maker could navigate difficult surfaces more effectively, leading to improved operational performance and reduced fuel usage.

Additionally, a logging business purchased sturdy undercarriage components for its forestry equipment. The upgraded elements showed prolonged life-span and boosted resistance to abrasion from rough terrain. The company experienced lowered upkeep costs and improved tools uptime, inevitably enhancing its lower line. These instance research studies highlight the tangible benefits of using durable undercarriage components in maximizing machinery performance and long life.

Final Thought

In final thought, making use of durable undercarriage components can significantly enhance efficiency and long life of heavy machinery. Instance studies have revealed that spending in durable undercarriage parts can lead to boosted overall performance and performance in various industries.The effectiveness and performance of these parts can substantially affect the total operation my latest blog post of machinery, making the option of durable undercarriage parts a vital choice for supervisors and drivers alike.Including resilient undercarriage components has actually shown significant enhancements in machinery performance. These case research studies emphasize the substantial benefits of using resilient undercarriage components in maximizing equipment efficiency and long life.

In verdict, making use of durable undercarriage parts can considerably enhance performance and durability of heavy machinery (undercarriage parts). Situation research studies have actually revealed that spending in sturdy undercarriage components can lead to boosted total efficiency and performance in numerous sectors

Report this wiki page